SMT is the abbreviation of Surface Mounted Technology, which is currently the most popular technology and process in the electronics assembly industry.

SMT production refers to the technological processes that are processed on PCB. (PCB means printed circuit board.)

SMT basic process:

- Solder paste printing.

- Component pick and place.

- Reflow curing and soldering.

- AOI automatic optical inspection.

- Maintenance and rework.

- PCB dispensing.

- PCB cleaning.

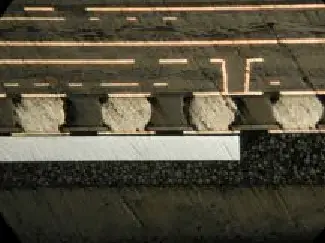

1. Solder paste printing: Its function is to print the lead-free solder on the PCB bare borad to prepare for the soldering of components. The equipment used is a screen printing machine, located after PCB loader of the SMT production line.

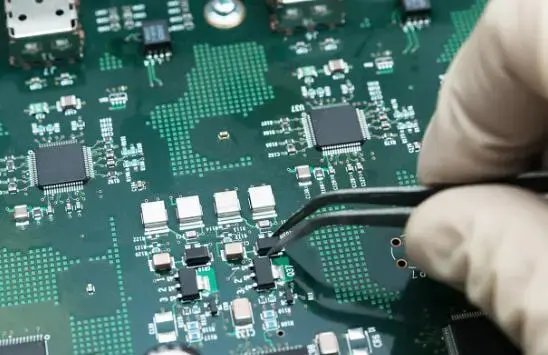

2. SMT pick and place: its function is to accurately install components to the fixed position of the PCB. The equipment used is a pick and place machine, located behind the auto solder machine in the SMT production line.

3. Reflow curing and soldering: its function is to melt glue and solder, so that the surface electronic components and the PCB board can be bonded together. The equipment used is a reflow oven, located behind the pick and place machine in the SMT production line.

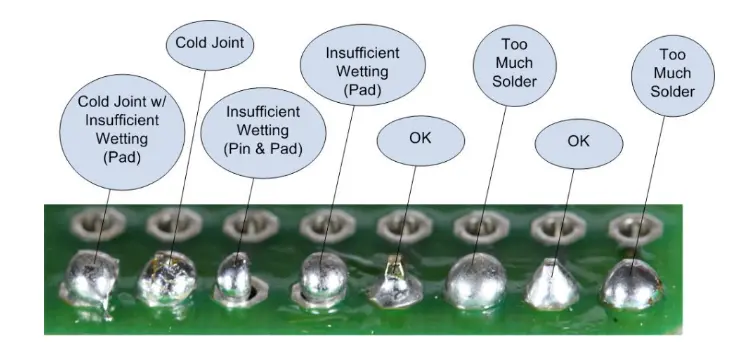

4. AOI optical inspection: its function is to auto-inspect welding and assembly quality of the assembled PCB board. The equipment used is automatic optical inspection (AOI), the order quantity is usually more than tens of thousands when using an online AOI, and the small order quantity is usually passed by manual inspection. The location can be configured in a suitable place on SMT production line according to the needs of inspection. Some are before reflow oven, and some are after reflow oven.

5. Repair: Its function is to repair failed PCB. The tools used are soldering iron, rework station, etc. Configured after AOI machine.

6. PCB dispensing: its function is to divide the multi-connected PCBA into individual units, generally using V-cut and a PCB router.

7. Washing the board: Its function is to remove the welding residues on PCBA such as flux which is harmful to the human body. It is divided into manual cleaning and washing machine cleaning, the location can be online or offline.

SunzonTech is leading company in providing SMT scheme in China. Always await for your kind enquiry.