Micro wave soldering machine

The application objects of microcomputer design are mainly research institutes, schools and other R&D departments. The production scope is adapted to the trial production of new products with multiple varieties, small batches and miniaturization, without the need for fixed operators. The design features of this type of model are: the wave crest width is usually not greater than 200mm,

The volume of the trough is not more than 50KG, small and exquisite, small footprint, easy to handle, particularly simple to operate, friendly man-machine interface, and strong fault tolerance.

Small wave soldering machine

The application scope of this type of model is medium and small batch production units and scientific research departments. It generally adopts a linear transmission method with high efficiency, the wave crest width is usually less than 300mm, and the solder tank has a medium capacity (single-wave model is usually less than 150kg, dual-wave model is less than 200kg),

The operating system is more complicated than a microcomputer, and its appearance is larger than that of a microcomputer. It can be a desktop or a floor-standing one. From the perspective of user usage, most scientific research departments are willing to choose such models to replace microcomputers, in order to have a larger choice in the scope of application.

Remember

price

between. Relatively speaking, the price of small wave soldering is relatively low, which can save costs for enterprises.

Medium wave soldering machine

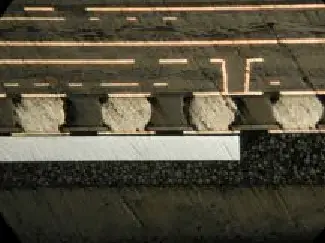

The application objects of medium-sized machines are medium and large-scale production units and enterprises. Its design features are: the model is large, the overall layout is a cabinet structure, usually the peak width is 300mm, and the solder tank capacity is greater than 200kg (single wave machine) or 250kg (double wave machine).

The large one can reach o0kqg, adopts frame-type or claw-type linear clamping method, which has complete functions, fast clamping speed and high operating efficiency. There are many accessories for users to choose, and it has good matching with the front and rear lines.

Large wave soldering machine

The mainframe is mainly designed for the needs of some advanced users. Its main design feature is to make full use of modern scientific and technological means and the latest achievements of wave soldering technology, pursuing perfect functions, advanced performance, intelligent control and modernization of the system. Such

The equipment is expensive, the maintenance is complicated, the welding quality is good, the efficiency is high, and the production capacity is large, so it is suitable for mass production.