Solder Balls:

- The silk-screen hole and the pad are not aligned, and the printing is not accurate, which makes the solder paste dirty the PCB.

- 2. The solder paste is exposed to too much in an oxidizing environment, and the moisture in the air is too much.

- Heating is not precise, too slow and uneven.

- The heating rate is too fast and the preheating interval is too long.

- The solder paste dries too fast.

- Insufficient flux activity.

- Too many tin powders with small particles.

- The flux volatility is inappropriate during the reflow process. The process approval standard for solder balls is: when the distance between the pads or printed wires is 0.13mm, the diameter of the solder balls cannot exceed 0.13mm, or there can be no more than five solder balls within a square of 600mm.

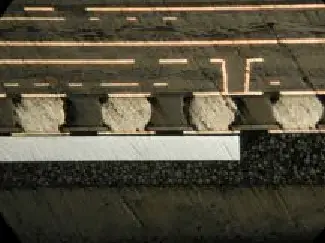

Bridging: Generally speaking, the cause of the solder bridge is that the solder paste is too thin, including the low metal or solid content in the solder paste, low thixotropy, easy squeezing of the solder paste, and too large solder paste particles. The surface tension of the flux is too small. Too much solder paste on the pad, too high peak reflow temperature, etc.

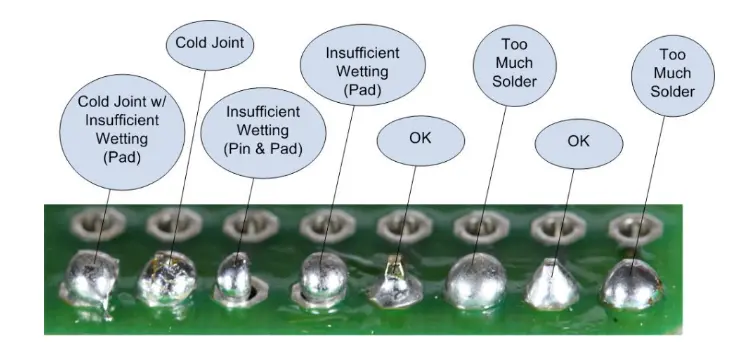

Open:

- 1. The amount of solder paste is insufficient.

- 2. The coplanarity of component pins is not enough.

- 3. The tin is not wet enough (not enough to melt, and the fluidity is not good), and the tin paste is too thin to cause tin loss.

- 4. The pin sucks tin (like rush grass) or there is a connection hole nearby. The coplanarity of the pins is particularly important for fine-pitch and ultra-fine-pitch pin components. One solution is to apply tin on the pads in advance. The pin sucking tin can be prevented by slowing down the heating speed and heating the ground more and less heating on the top. It is also possible to use a flux with a slower wetting speed and a high active temperature or a solder paste with different ratios of Sn/Pb to retard melting to reduce the pin sucking.