The main purpose of adding nitrogen (N2) to the SMT reflow oven is to reduce the oxidation of the welding surface and improve the wettability of the welding. Because nitrogen is a kind of inert gas, it is not easy to produce compounds with metals, and it can also isolate oxygen and metals in the airto prevent oxidation reaction from happening.

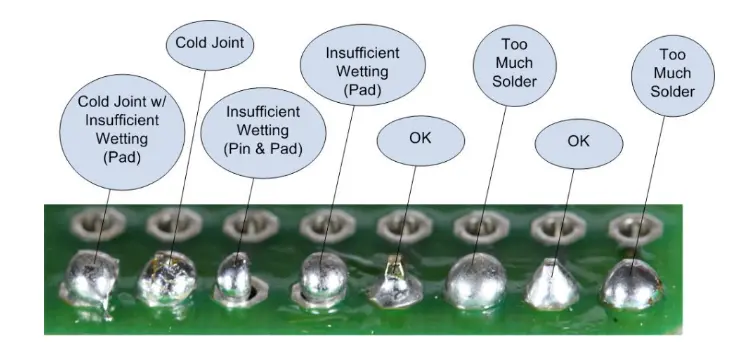

Firstly, the principle of using nitrogen to improve the solderability of SMT is based on the fact that the surface tension of solder under a nitrogen environment will be lower than when exposed to the atmosphere, so that the fluidity and wettability of the solder are increased.

Secondly, nitrogen reduces the concentration of the original oxygen abd the substances which will contaminate the soldering surface, this kind of function can greatly reduces the oxidation effect of high-temperature soldering, especially in the improvement of the quality of the second side reflow.

Nitrogen is not a panacea for PCB oxidation. If the surface of parts or circuit boards has been severely oxidized, nitrogen cannot bring them back to life, and nitrogen can only have a remedial effect on slight oxidation (remedy, not solution)

Advantages of nitrogen reflow oven:

Reduce oxidation.

Improve welding ability.

Enhance solderability.

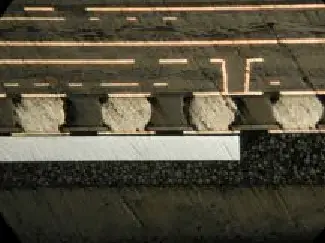

Reduce voiding rate. Because the oxidation of the solder paste or solder pad is reduced, the fluidity of the solder becomes better.

Disadvantages of reflow soldering and nitrogen:

High cose.

Increase the chance of tombstone generation

Enhance capillary phenomenon (wick effect)

What kind of circuit boards or parts are suitable for nitrogen reflow?

OSP surface treatment dual-sided reflow board is suitable to use nitrogen reflow oven.

It can be used when the part or circuit board does not eat tin well. Such as increasing the wettability of QFN to eat tin.

Large package and high density BGA.