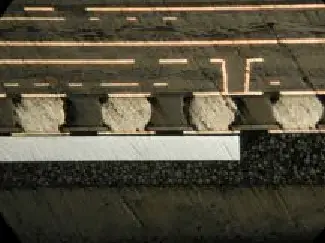

Reflow oven is one of the core machine of a smt production line. It mainly melts the solder paste and welds the electronic components with PCB pads. The temperature profile and temperature control of the reflow oven have a great influence on the soldering quality of the PCB. Generally, reflow oven is divided into four different temperature zones and each zones have different functions, so what is the function of each temperature zone of reflow oven? The following SunzonTech will explain to you the function of each temperature zone of reflow oven.

What are the four temperature zones of reflow oven?

Reflow oven is generally divided into four temperature zones, which are preheating zone, heat absorption zone, reflow zone, and cooling zone. Different temperature zones correspond to different reflow effects and reflow temperature curves.

Preheating zone function of reflow oven

The function of preheating zone is to activate the solder paste, let the solder paste start to move, and the solder material reaches thermal equilibrium. The flux volatilizes with the rise of temperature. The heating rate of the preheating zone should be controlled within an appropriate range. If it is too fast, it may damage the components. If it is too slow, it may affect the welding quality.

heat absorption zone function of reflow oven

The heat absorption zone is to stabilize the temperature of various components in the reflow oven. Because the size of each component on the PCB is different, the small component heats up quickly and the large component heats up slowly. In order to achieve the temperature balance of each component, the flux need to be fully volatilized to reduce the welding bubble rate.

Reflow soldering zone of reflow oven

The temperature in the reflow soldering zone of the reflow oven is the highest comparing to other zones, the tin powder metal substance in the solder paste is fully melted and the flux is fully volatilized. The residence time in the reflow soldering zone of the reflow oven should not be too long or it may damage the PCB and the components.

Cooling zone of reflow oven

When the temperature is cooled below the solidification point of the solder paste, the solder joints will solidify. The faster cooling effect it is, the better soldering quality it will have. If the cooling speed is too slow, the solder paste may oxidize with the moisture in the air, which would cause bad soldering quality.

Welcome to contact SunzonTech for support of your reflow oven process. We provide SMT service with many years experience and we are always ready to help you.

Contact: sales@sunzontech.com