At present, the electronics industry basically belongs to the traditional semiconductor industry, and the equipment used in manufacturing is quite large, costly, and low in manufacturing efficiency; the entire concept of flexible electronics is to use traditional semiconductor products, components and circuits to print Substitute. The differences between flexible electronics and traditional electronic circuits are mainly seen from three aspects:

(1) Application prospects

Once a very soft substrate is applied to the design or the circuit is made into an invisible or foldable thing, it is very different from the traditional hard substrate.

(2) Manufacturing cost

Flexible electronics uses a roll-to-roll printing process, and the use of materials can also avoid the problem of wasting more than 95% of materials like photolithography. The area printed by printing is equivalent to the area used, and its utilization rate is More than 90%, from the perspective of long-term development, the cost of printing will be much lower than that of traditional photolithography; the general cost of silicon CMOS wafers is US$10 per square centimeter, compound semiconductors are even more expensive, and the ideal cost for flexible electronics is USD 0.1 per square centimeter, the huge advantage of flexible electronics can be seen from the cost.

(3) Investment perspective

Traditional semiconductor factories require billions or even tens of billions of investment at every turn, but the method of flexible electronic printing is like traditional printing, and a basic scale can be established by investing tens of millions. It should be emphasized that the ink used for printing is different from traditional printing and needs to be specially developed. The initial cost of development is relatively high due to the small quantity, but the cost will become lower after mass production.

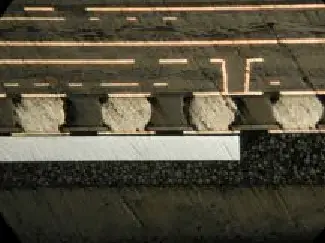

Structure and materials of flexible electronic systems

Although flexible electronic technology can be applied in different fields, its basic structure is similar, including at least the following four parts: electronic components, flexible substrate, cross-linked conductor (finterconnect) and adhesive layer.