Panasonic NPM SMT Pick and Place machine | SunzonTech

- High productivity dual rail mounting method

Industry leading mounter productivity: when 3 NPM pick and place machine are connected, the mounted speed will reach to 171,000 cph and the productivity per unit is 27,800 cph/ m².

Dual lane conveyor belt: When components are mounted on one rail, the PCB board can be replaced on the other rail to improve productivity and realize the production of dissimilar PCB board.

- High function & high reliability:

Inherit Panasonic’s DNA: Fully compatible with CM Series hardware.

It has the ability to correspond to 0402-100*90mm components, with functions such as component thickness inspection and PCB board bending inspection, which can greatly improve the quality of mounted process and fully meet the needs of customers who have difficult processes such as POP and FPC.

- Simple operation:

The smart HMI design and the model switching instructions can greatly shorten the PCB exchange time, which will also increase the productivity of SMT production line.

- Mounting head type:

High speed and general purpose

- Number of nozzles:

12 nozzles, 8 nozzles, 2 nozzles

- Mounting speed:

0.063 s/chip

0.106 s/chip

0.423 s/QFP

- Mounting accuracy:

±40μm/chip

±40μm/chip

±30μm/QFP

- Number of feeders:

Maximum 68 feeders(8mm double, small reel)

- Corresponding component size:

0402~L12mm*W12mm*T6.5mm

0402~L32mm*W32mm*T12mm

0603~L100mm*W90mm*T28mm

- PCB size range of single lane conveyor system:

L50mm*W50mm~L510mm*W480mm

- PCB size range of dual lane conveyor system:

Dual lane mode: L50mm*W50mm~L350mm*W216mm

Single lane mode: L50mm*W50mm~L350mm*W460mm

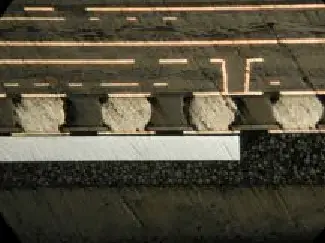

- High productivity—using dual-lane PCB solder printing

Productivity per unit area is up to 47% (compared to the previous model SP18P-L)

Switching function of the next model in operation: Because the printing base is equipped on the front and back, it can be operated completely independently, and the model can be switched on the other side when the production is continued on one side.

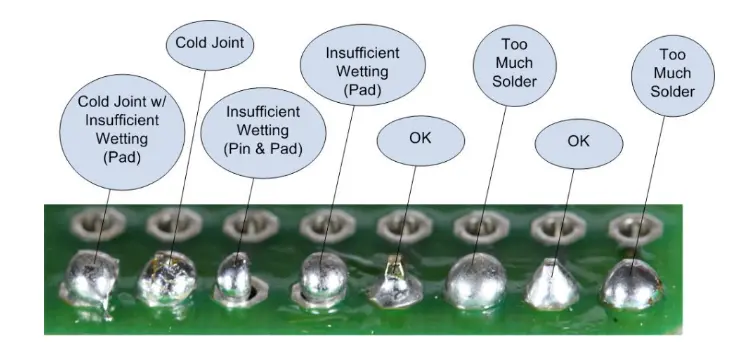

- High-quality printing

Inherit Panasonic NPM unique printing DNA: DC printing process + high speed multiple stripping + gentle cleaning + advanced squeegee holder: to ensure high quality printing.

Solder Paste Inspection (SPI)—APC System.

Feedback to solder paste printer: It can realize printing position correction, cleaning command, and stop command in case of sudden defects.

Feed forward to head of mounter: provide solder paste position information and block, bad mark information communication

Feed forward to AOI: APC component placement position information.

- Inspection after installation (AOI)

Inspection after mounting.

Inspection before mounting: PCB board body inspection before BGA mounting & inspection of sealed enclosure before mounting.

For more knowledge about pick and place machines and surface mount technology, please contact: