The reflow oven has 4 main sources of danger: high voltage, high temperature, heat insulation materials, and moving mechanical parts such as the sprocket and pulley of the drive system. Under normal operation and maintenance of equipment, these hazards are effectively prevented through machine design and correct operation and maintenance.

Safety operation rules of reflow oven:

Equipment shutdown maintenance requires 2 or more people; one person is responsible for computer control, and one person is responsible for observing system operation.

Safety protective work clothes should be worn when operating and maintaining equipment.

Before performing maintenance on the equipment, turn off the power and air supply.

The equipment should avoid shaking and vibration during transportation. Sudden shaking and vibration can damage the equipment.

Do not arbitrarily cancel the safety switch of the machine or the safety performance of the machine itself.

Pay attention to all warning labels and do not move the warning labels on the device randomly.

The equipment must not work with faults or hidden dangers.

Turn off the power of the equipment before wiring or disconnecting.

Turn off the power and disconnect the power plug before moving the device.

SER series reflow ovens use high-voltage power supplies. When the machine is working, do not touch the parts with high-voltage power supply on the machine with your hands, otherwise it will cause serious harm or even death.

The heat insulation material of the reflow furnace is not exposed under normal operating conditions, and is only exposed when the furnace is opened to maintain the furnace. At this time, you should be careful to avoid inhaling fibers, and wear protective masks, gloves and work clothes as required.

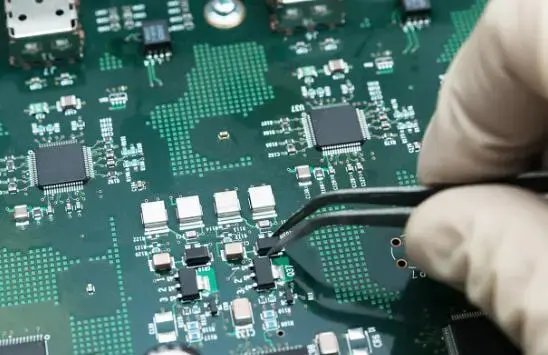

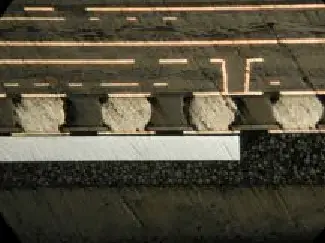

The moving parts go through the entire furnace. Do not touch the moving parts, such as chains, sprockets, pulleys, etc., when operating; when performing maintenance, move the parts carefully and turn off the power as much as possible.

Be careful to avoid touching the heating element to avoid burns or burning consequences.

Reflow oven safe operation inspection:

The machine only operates when the safety device is in effect.

Before turning on the machine switch, make sure that the machine will not hurt anyone when it starts.

Check whether the safety device is damaged to ensure that the safety device is at least effective once the machine malfunctions.

The safety devices of this machine include: emergency brake switch, main power switch, three-color light, machine cover, electric control box, etc.

Reflow furnace maintenance and troubleshooting:

Regular maintenance should be institutionalized.

Before inspection and maintenance, be sure to turn off the power switch to ensure that the equipment is in a shutdown state.

Check the connecting screws of moving parts such as gears and pulleys to ensure that they are connected reliably.

Warning signs should be erected to indicate the status of the machine to prevent the machine from being activated by a third party while it is under maintenance.

Once the repair work is completed, an inspection should be carried out to ensure that the device is fully installed and functional.