TV assembly line production line TV assembly line for TV manufacturing

SunzonTech TV assembly Line production line:

We have served lots of customers building their own production TV assembly line or expanding their production area.

We can always know what is the most perfect scheme of customer’s wishes.

Customers can not only join the design of TV assembly line but they can also put much thoughts on the design.

We are always open and try our best to match the requirement of our customers.

Many levels of solution with many levels of cost.

Using strong material to meet the high quality.

High quality motor in famous brand.

Share to:

Contact us to design the most suitable TV production assembly line for your factory layout!

SunzonTech is the professor of assembly line and automatic solution field.

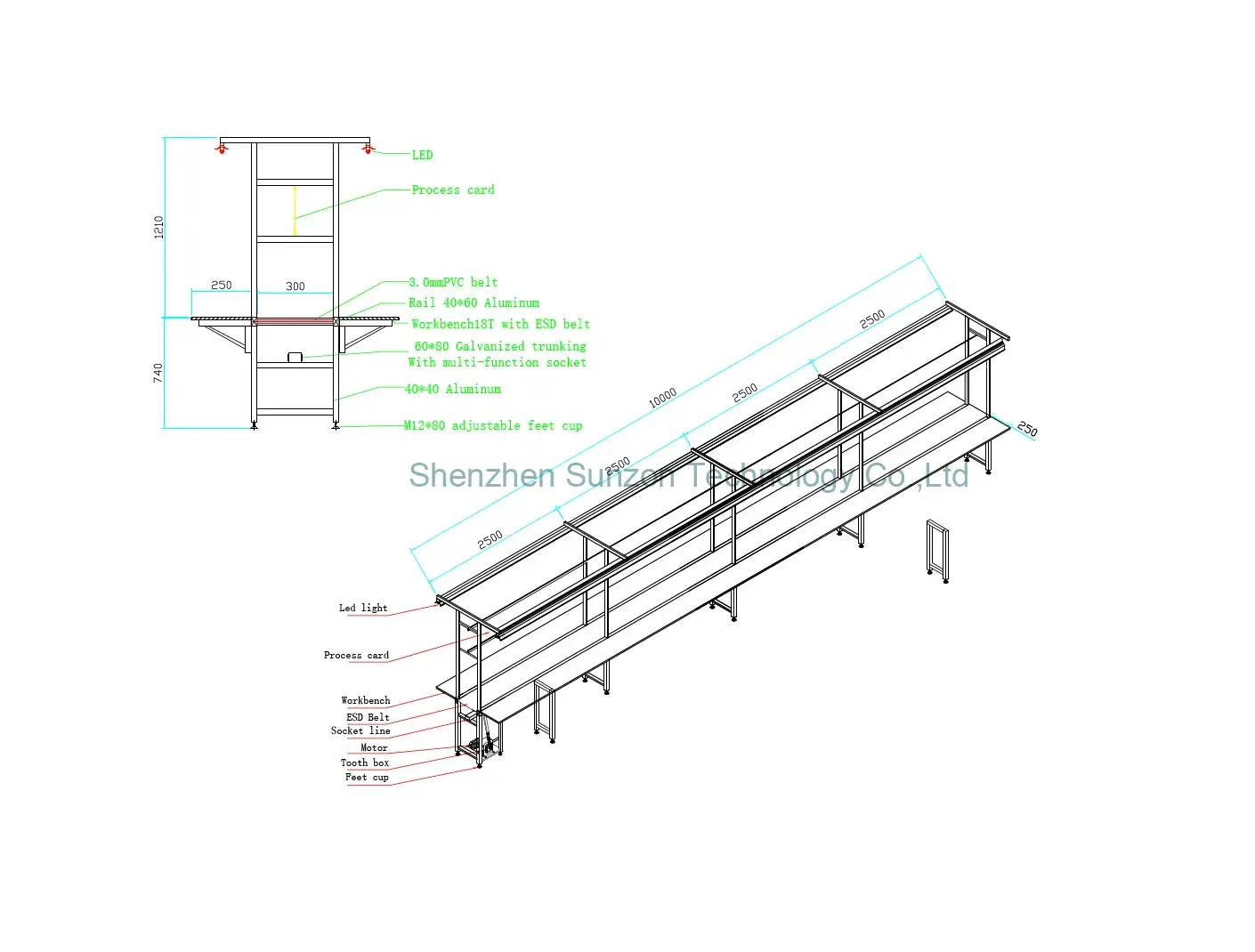

Configurations Of TV Assembly System From SunzonTech

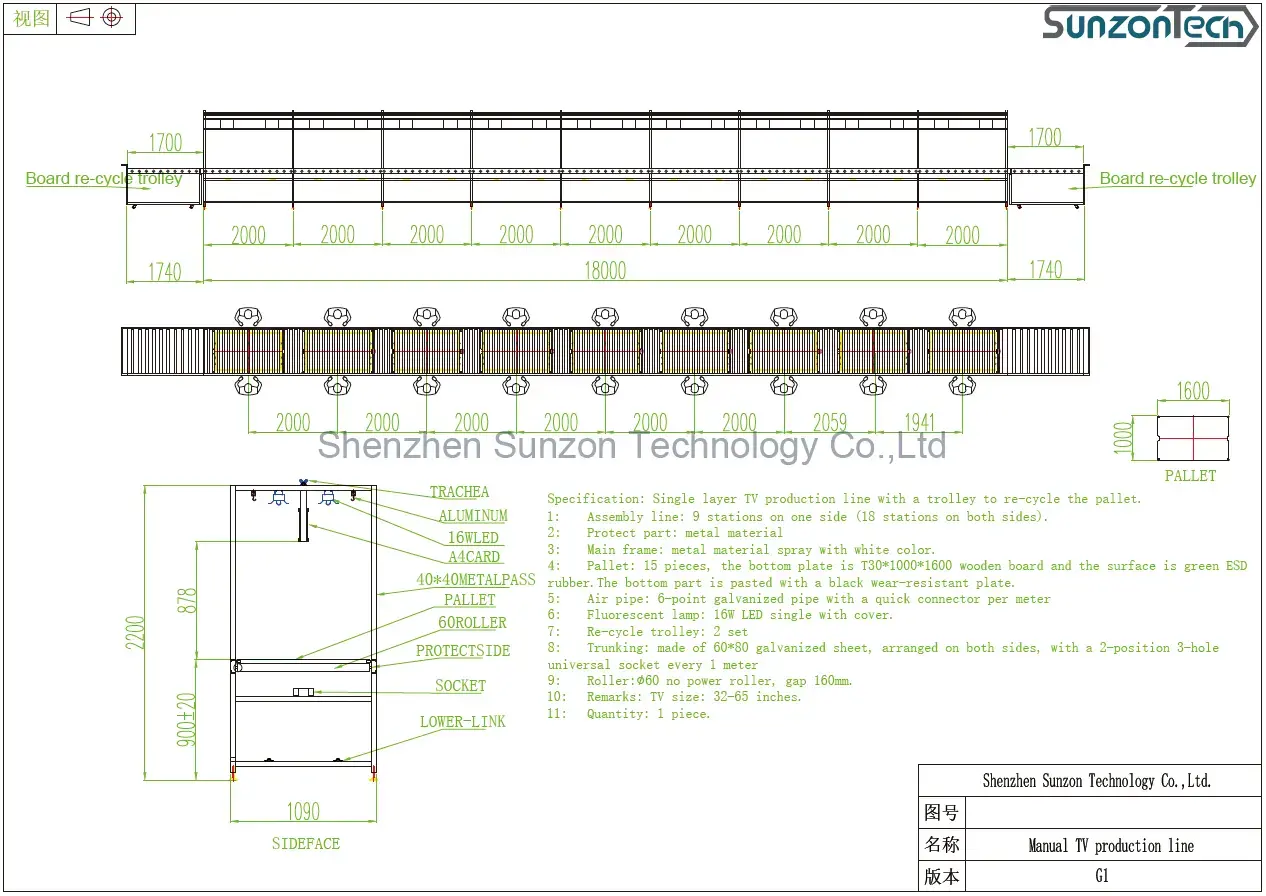

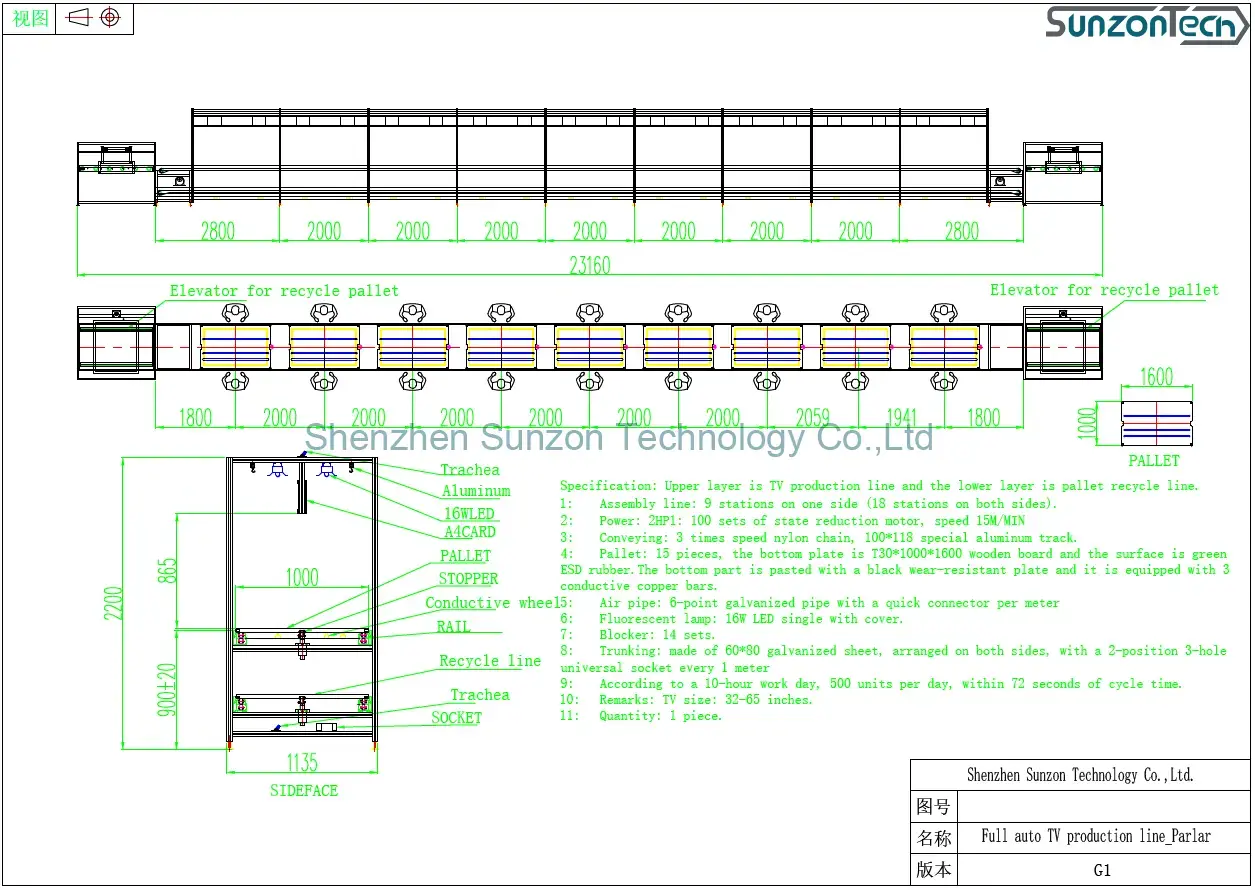

| (L)23.16m*(W)1m*(H)0.9m TV assembly line With auto re-cycle pallet system | ||||||

| No. | Items | Specification and material of TV assembly line | Quantity | |||

| 1 | Specifications | (L)23160*(W)100*(H)900±20mm | 1 unit | |||

| 2 |

Motor of TV assembly line |

1. The motor head is welded with 50*50 square iron, the outer is covered by iron plate, and the surface is sprayed with powder. 2. The power of motor adopts 2HP Taiwan “JSCC” gear reduction motor. 3. The frequency converter adopts 2HP “ADLEE” or “SINEE”. 4. The speed adjustment range is 0-15m/min; 5. Assembly line with a pallet re-cycle system. |

2 sets | |||

| 3 | Structure | 1. The frame is made of 50×50*2.0mm aluminum material; 2. The guide rail is made of 118*100MM aluminum material; 3. The chain of rail will use SUZHOU “2060” 3 time speed special chain. |

23.1m | |||

| 4 | Power | 1. The lower part of the conveyor body is equipped with sockets, will have one socket per 1m. 2. The wires are “Jinhuanyu” 6 square wires. 3. The wire trough is made of galvanized sheet and the size is 60×80×0.8 mm; |

18 units | |||

| 5 | Air source | The main air tube using 6 fen galvanized tube, every work station will equip with a fast connector. | 15 units | |||

| 6 | Elevator | 1. Main body is welded with 50*50 square iron, sprayed with powder. 2. The lifting action adopts air cylinder to lift, equipped with solenoid valve, 3. The transmission power adopts 120W Taiwan “VTV” motor, driving two 50MM wide non-slip belts. |

2 sets | |||

| 7 | Stopper | Control blocker: 1 set (QX-2 single-acting cylinder with buffer, solenoid valve control,) Work station stopper: 11 sets (QX-2 with buffer single-acting cylinder, equipped with manual control valve control) |

3 units

14 units |

|||

| 8 | Electrical control system | “Panasonic” PLC control Main switch adopts “Chint” Leakage switch adopts “Chint” The distance switch adopts “Omron” AC contactor adopts “Chint” Relay adopts the Japanese “Omron” “Chint” power supply, running indicator light |

1 set | |||

| 9 | Pallet | Specification: 1600mm*1000mm*T25M for 65” TV assembly line The pallet adapt 25m board, with green belt surface, fireproof board is attached to the bottom, the stopper gap is opened on both sides in the direction of 1600MM, and the “T” rubber strip is edging. |

15 units | |||

1. SunzonTech always has many stocks of standard machine. So the day you order will be the day we are able to ship the machine.

2. SunzonTech has a mature supply chain which response quickly. So we are able to coordinate all projects and provide you the shortest lead time.

3. The shortest lead time of SunzonTech is 14 days after the deposit!

1. SunzonTech is a leading PCB handling machine manufacturer in China.

SunzonTech is able to design, R&D and produce all types of PCB handling machine according to the requirement from customer.

2. All PCB handling machine will equip with strong material structure and famous brand parts.

3. SunzonTech is able to provide 3D drawing for customer who order customized PCB handling machine.

4. The customized machine will be 100% meet customer’s requirement, no matter in material or parts.

5. OEM service is also allowed in SunzonTech.

6. SunzonTech is able to provide the most professional and cost saving proposal of PCB handling machine for your SMT production line.

1. SunzonTech will provide one year gurrantee and life long maintenance for all machines from SunzonTech. Parts will provide for free for period of warranty.

2. On site service is available in many areas such as Vietnam, Philippine, Mexico, Thailand etc.

3. SunzonTech will hear all requirement from customer and find every possible way to solve the problem. We are always hearing and supporting.

4. SunzonTech will update status of order periodically to let customer better know the status of their order.

Production Line

PCB Cooling Conveyor

PCB Cooling Conveyor With Lift Cover

PCB Vaccum and Magazine Loader

Two System Conbine Loader - Vaccum and Magazine System

PCB Cover Conveyor

PCB Conveyor With Further Dust Cover

PCB Shuttle Conveyor Traverser

PCB Cooling Conveyor With Lift Cover

PCB Buffer Machine

PCB Dual Rail SMT Buffer Machine

ESD Belt Conveyor

ESD Belt Conveyor With Turning Solution

PCB Turning Conveyor

PCB Turning Conveyor To Change Direction In SMT Production Line

PCB Shuttle Conveyor

PCB Shuttle Conveyor 5.5 Meter Long

PCB Guide Conveyor

PCB Guide Conveyor To Guide PCB Into Rail System

PCB Magazine Unloader

PCB Magazine Unloader For Standard PCB Magazine Size

PCB Gate Conveyor

PCB Gate Conveyor Manually Lift Type

PCB Conveyor

SMT PCB Standard Conveyor

Message

- Shenzhen Sunzon Technology Co., Ltd.

- +86 13417069748

- +86-755-27307103

- sales@sunzontech.com

- Building 45, Hengkeng Industrial Zone, Genzhuyuan Community, Matian Street, Guangming District, Shenzhen, China

Philippine Branch: