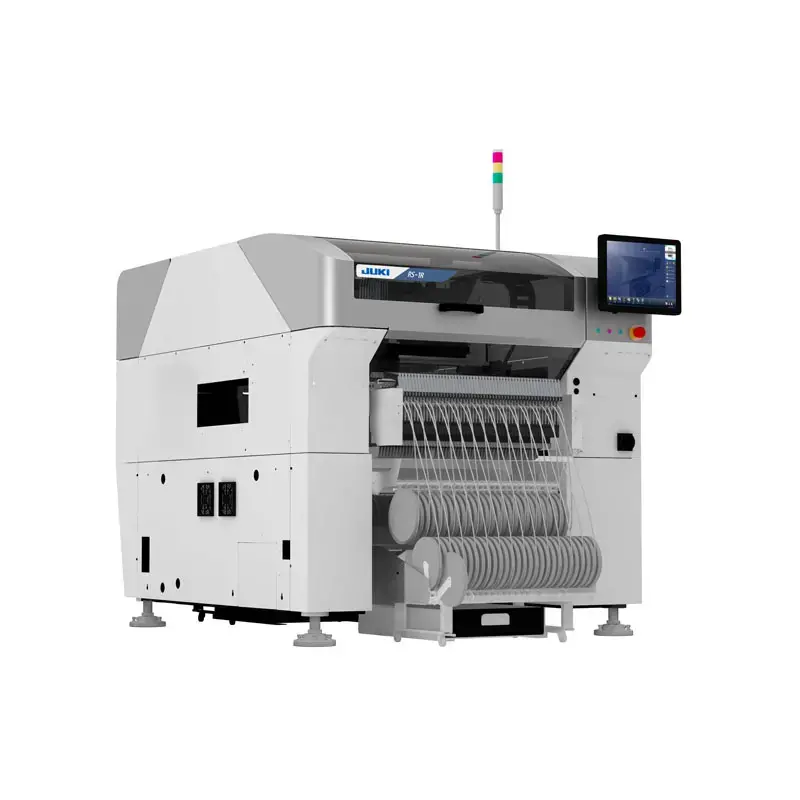

JUKI KE-3000 Speed & Flex Mounter Chip Shooter for PCB manufacturing SMT production

JUKI’s KE-3000 chip shooter is a high-speed flexible placement supplier meeting various expectations.

JUKI’s KE-3010 chip shooter takes on the job of placement from ultra-small components while JUKI’s KE-3020 chip shooter is called in to action regarding placement with large and odd-shaped components.

Both machines operate with a simultaneous, instantaneous centring of components in favour of a high-speed production.

Share to:

| Board size | L size: | 410 × 360 mm, Application of long PCB*1 800 × 360 mm | |

| L-Wide size: | 510 × 360 mm, Application of long PCB*1 1,010 × 360 mm | ||

| XL size: | 610 × 560 mm, Application of long PCB*1 1,210 × 560 mm | ||

| Component height | 6 / 12 mm (KE-3010) 12 / 20 / 25 mm (KE-3020) |

||

| Component size | KE-3010 chip shooter | 0402 (01005) ~ 33.5 mm (Laser recognition) 3 mm*2 ~ 33.5 mm (Vision recognition, Standard camera) 1.0 × 0.5 mm*3 ~ 20 mm (Vision recognition, High-resolution camera) |

|

| KE-3020 chip shooter | 0402 (01005) ~ 33.5 mm (Laser recognition) 3 mm ~ 74 mm / 50 × 150 mm (Vision recognition, Standard camera) 1.0 × 0.5 mm*3 ~ 48 mm or 50 x 120 mm (Vision recognition, High-resolution camera) |

||

| Placement Rate | Optimum | 23,500 CPH (KE-3010), 20,900 CPH (KE-3020) | |

| IPC9850 | 18,500 CPH (KE-3010), 17,100 CPH (KE-3020) | ||

| IC*4 | 9,000 CPH*5 (KE-3010), 9.470 CPH*5 (KE-3020) | ||

| Placement accuracy | KE-3010 chip shooter | Laser recognition ± 0.05 mm (± 3 σ), Vision recognition ± 0.04 mm | |

| KE-3020 chip shooter | Laser recognition ± 0.05 mm (± 3 σ), Vision recognition ± 0.03 mm (MNVC ± 0.04 mm) | ||

| Feeder inputs | max. 160 in case of 8 mm tape (electric double tape feeder)*6 | ||

| Power supply | 200 – 415 VAC, 3-phase | ||

| Apparent power | 2.2 kVA | ||

| Operating air pressure | 0.5 ± 0.05 Mpa | ||

| Air consumption | 50 L / min | ||

| Machine dimensions(WxDxH) | 1,500 × 1,690 × 1,500 mm (L size) 1,800 × 1,690 × 1,500 mm (L-Wide size) 2,131 × 1,890 × 1,500 mm (XL size) |

||

| Mass(approximately) | 1,900 kg (L size) 2,250 kg (XL size) |

||

| others | >The application of long PCBs is optional. >When using MNVC (option). >KE-3010A: when using the high-resolution camera and MNVC (option); KE-3020VA: when using the high-resolution camera (option). >Effective cycle time: the IC placement speed indicates an estimated value obtained when the machine places 36 QFP (100 pins or more) or BGA components (256 balls or more) on an M size board (CPH = number of components placed in one hour). >Estimated value when using MNVC and picking up components simultaneously with all nozzles. MNVC is optionally available for KE-3010A; MNVC is standard equipment for KE-3020VA & KE-3020VRA. >When using the EF08HD electric double tape feeder. >Display not included in height. >Dimensions of machine described for conveyor height of 900 mm. |

||

1. SunzonTech always has many stocks of standard machine. So the day you order will be the day we are able to ship the machine.

2. SunzonTech has a mature supply chain which response quickly. So we are able to coordinate all projects and provide you the shortest lead time.

3. The shortest lead time of SunzonTech is 14 days after the deposit!

1. SunzonTech is a leading PCB handling machine manufacturer in China.

SunzonTech is able to design, R&D and produce all types of PCB handling machine according to the requirement from customer.

2. All PCB handling machine will equip with strong material structure and famous brand parts.

3. SunzonTech is able to provide 3D drawing for customer who order customized PCB handling machine.

4. The customized machine will be 100% meet customer’s requirement, no matter in material or parts.

5. OEM service is also allowed in SunzonTech.

6. SunzonTech is able to provide the most professional and cost saving proposal of PCB handling machine for your SMT production line.

1. SunzonTech will provide one year gurrantee and life long maintenance for all machines from SunzonTech. Parts will provide for free for period of warranty.

2. On site service is available in many areas such as Vietnam, Philippine, Mexico, Thailand etc.

3. SunzonTech will hear all requirement from customer and find every possible way to solve the problem. We are always hearing and supporting.

4. SunzonTech will update status of order periodically to let customer better know the status of their order.

Production Line

PCB Cooling Conveyor

PCB Cooling Conveyor With Lift Cover

PCB Vaccum and Magazine Loader

Two System Conbine Loader - Vaccum and Magazine System

PCB Cover Conveyor

PCB Conveyor With Further Dust Cover

PCB Shuttle Conveyor Traverser

PCB Cooling Conveyor With Lift Cover

PCB Buffer Machine

PCB Dual Rail SMT Buffer Machine

ESD Belt Conveyor

ESD Belt Conveyor With Turning Solution

PCB Turning Conveyor

PCB Turning Conveyor To Change Direction In SMT Production Line

PCB Shuttle Conveyor

PCB Shuttle Conveyor 5.5 Meter Long

PCB Guide Conveyor

PCB Guide Conveyor To Guide PCB Into Rail System

PCB Magazine Unloader

PCB Magazine Unloader For Standard PCB Magazine Size

PCB Gate Conveyor

PCB Gate Conveyor Manually Lift Type

PCB Conveyor

SMT PCB Standard Conveyor

Message

- Shenzhen Sunzon Technology Co., Ltd.

- +86 13417069748

- +86-755-27307103

- sales@sunzontech.com

- Building 45, Hengkeng Industrial Zone, Genzhuyuan Community, Matian Street, Guangming District, Shenzhen, China

Philippine Branch: