- Principle of X-RAY inspection machine

First of all, X-RAY equipment mainly uses the penetrating effect of X-ray rays. X-ray have a short wavelength and extremely large energy. When they are irradiated on a substance, the substance can only absorb a small part, while most of the Energy will pass through the gaps between the atoms of matter, showing a strong penetrating ability.

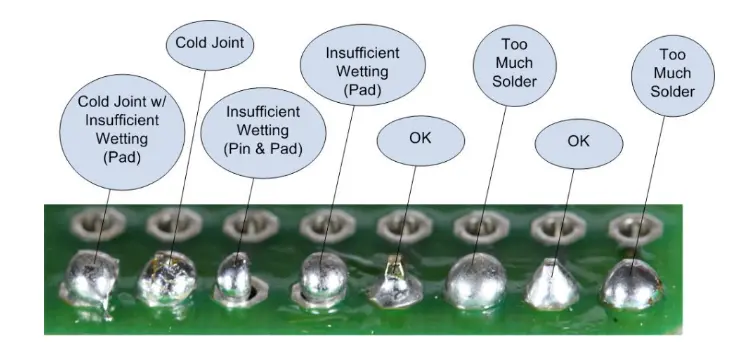

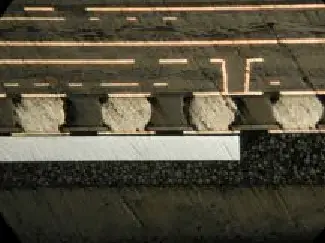

- The x-ray equipment can detect the relationship between the penetrating power of X-rays and the density of the substance. The property of differential absorption can distinguish substances with different densities. Therefore, if the inspected article is broken, the thickness is different, and the shape changes, the absorption of X-ray rays is different, and the resulting image is different, so it can produce a differentiated black and white image.

- It can be used for IGBT semiconductor inspection, BGA chip inspection, LED light bar inspection, PCB bare board inspection, lithium battery inspection, non-destructive inspection of aluminum castings.

- Simply put, it is to output high-quality fluoroscopy images by using a non-destructive micro-focus x-ray device, and then convert the signal received by the flat panel detector. All functions of the operating software can be completed with only a mouse, which is very easy to use. Standard high-performance X-ray tubes can detect defects below 5 microns, some x-ray equipment can detect defects below 2.5 microns, the system magnification can reach 1000 times, and objects can move and tilt. Manual or automatic detection can be performed through x-ray equipment, and detection data reports can be automatically generated.

- Industrial X-RAY testing equipment has a wide range of applications. Commonly used in the battery industry such as lithium battery testing, circuit board industry, semiconductor packaging, automotive industry, circuit board assembly (PCBA) industry, etc., to observe and measure the internal objects after packaging Position and shape, find problems, confirm whether the product is qualified, and observe the internal condition.

- Mainly used for SMT, LED, BGA, CSP flip chip inspection, semiconductor, packaging components, lithium battery industry, electronic components, auto parts, photovoltaic industry, aluminum die casting, molded plastic, ceramic products, etc. Special industry testing.