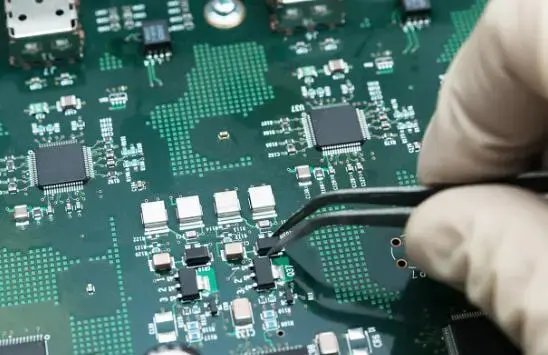

SMT is to take out the surface mount components such as SMC/SMD from its packaging structure, and then paste it on the designated pad position of the PCB. English calls this process “Pick and Place”, which is also some guesses It is called “pick and put” in the patch. Of course, the orientation of the solder pad must be coated with solder paste, or although no solder paste has been applied, patch glue has been applied to the PCB surface covered by the components. After placement, the components rely on the adhesive force of solder paste or patch glue to initially stick to the specified pad position.

In industrial production, the placement process is completed by a special placement machine-placement machine. Placement machine, also known as “placement machine”, is a special machine that replaces manual placement. The basic placement machine is composed of a frame, a circuit board clamping organization, a feeder placement head, a suction nozzle, and XY and z axes. In addition to moving in the z direction, the z axis can also rotate in the θ direction.

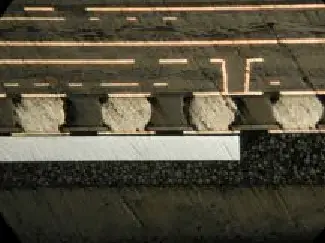

Typical reflow soldering process production line

In industrial production, the SMT process is realized through the production line method. The production line is also called the production assembly line, which is the basic mode of modern large-scale production. The relatively basic SMT production line consists of 3 typical processes and corresponding equipment: printing, patching and reflow soldering.

The placement machine is generally composed of a high-speed placement machine and a multi-function placement machine. In a production line, only one printing machine and one reflow soldering machine are required. In actual production, the number of placement machines and variety requirements are optimized according to the production model and product type of the factory. For example, 4 or more placement machines are equipped. Therefore, the length of the SMT line body mainly depends on the number of placement machines. Of course The placement machine is also more important in the entire smt production line.