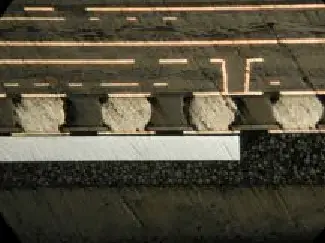

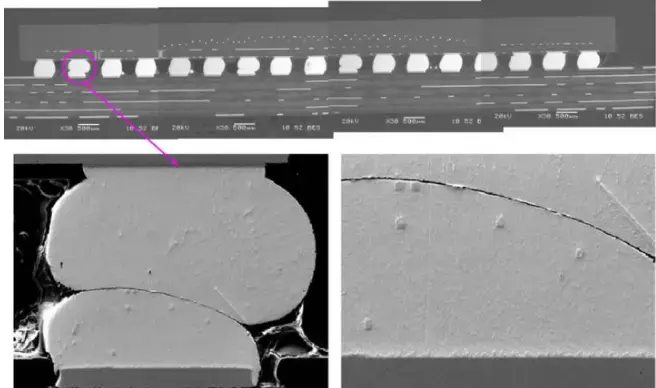

Defect 1: Connecting tin

Connecting tin is also called short circuit, which means the solder ball and the solder ball are short-circuited during the soldering process. Two pads are connecting together which causing a short circuit of two BGA board.

★Solution: the factory should adjust the temperature curve, reduce the reflow air pressure, and improves the solder printing quality.

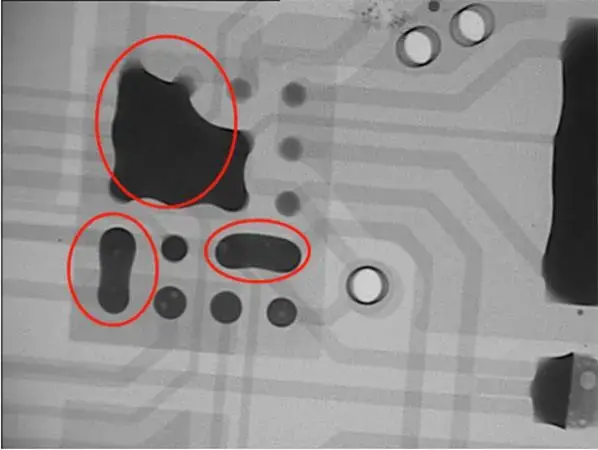

Defect 2: fake welding

False soldering is also called “Head-in-Pillow (HIP)”. There are many reasons for fake soldering:

1. Oxidation of solder balls or PAD.

2. Insufficient temperature in the reflow oven.

3. PCB deformation,

4. Poor solder paste activity

BGA fake welding is characterized by “difficult to find” and “difficult to identify”.

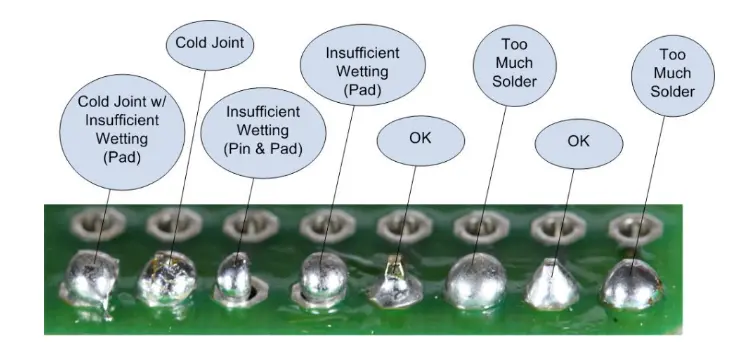

Defect 3: cold welding

Cold soldering is not exactly the same as fake soldering. Cold soldering is caused by the abnormal reflow temperature. The abnormal temperature will cause the solder paste not melt completely. It may be caused by the temperature not reaching the melting point of the solder paste or insufficient reflow time in the reflow zone.

★Solution: the factory need to adjust the temperature curve and reduce vibration during the cooling process.